|

|

|

|

|

|

|

|

|

|

|

|

|

|

VRI™ - Variation Reduction Initiative successful implementation at Multek.The PCB group of Flextronics International Ltd. |

| Our Quality Philosophy | Integrating Mergers & Acquisitions |

|---|---|

|

In a continuing effort to foster the integration of all (M&A) sites worldwide, and to promote the "one-look-one-feel " work environment, MPW focus his attention on:

|

|

To unify all sites and to further promote "one-look-one-feel", Corporate quality goals and objectives were established and published in a full color, detailed brochure for internal distribution and for customer awareness. |

| A Training Curriculum for all Employees of the Organization |

|---|

|

Every director, manager, and engineer received the same level of advanced training regardless of their involvement with the VRI plan. Why? The reason is simple.

There is no reliable, long-term benefit for the organization which has only one, or a few, well-trained, prepared and skillful individuals who are subject matter experts (SME’s) on critical business processes. Inevitably, when such SME’s communicate, the non-experts do not understand what the SME’s are talking about. The non-experts cannot even ask questions, factually challenge action-decisions, or propose informed, viable alternatives. And just as inevitably, this schism between the knowledge "haves" and the "have-nots" yields frustration, conflict and the likely failure of the organization’s change and improvement initiatives. |

| Global Corrective Action/RPM Enterprise System | CA/RPM |

|---|---|

|

At Multek, the globalization of the CA/RPM system significantly improved response levels and interaction with customers, and raised the scientific professionalism of the organization when dealing with problem-solving. |

| The Global Corrective Action System (CA/RPM) was merged with a methodology for rapid problem identification, analysis, response and resolution, and developed into an Internet/Intranet software enterprise solution. | |

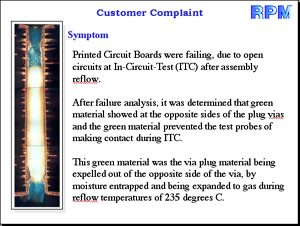

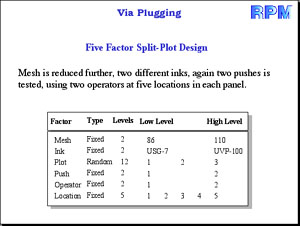

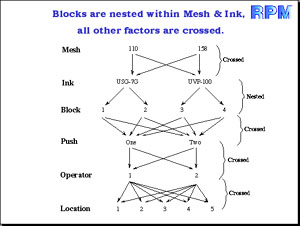

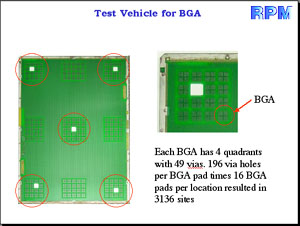

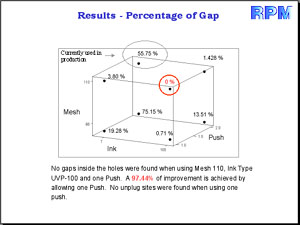

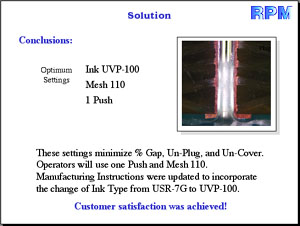

| Rapid Problem-Solving Methodology | BGA Via Plug Example |

|---|---|

|

|

| The Rapid Problem-Solving Methodology (RPM), a proprietary methodology of ASC, teaches all the steps necessary to correct problems. It was designed to speed up the execution of problem solving, specifically when responding to a customer complaint or to a stoppage on a production line. | |

|

|

|

|

| Monthly VRI Presentation | ENIG - Electroless Nickel/Immersion Gold |

|---|---|

|

|

| Presenting the Characterization of ENIG. |

| Inter-Factory Product Transfer |

|---|

|

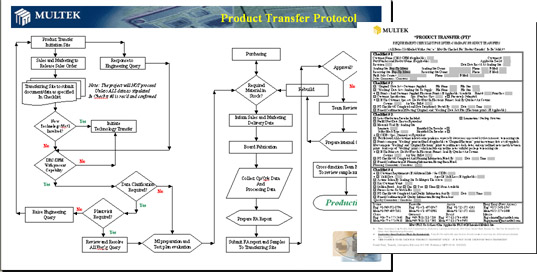

| A typical problem experienced by many global organizations is the transfer of product to a low-cost facility. To make the transfer seamless an Inter-Factory Product Transfer Protocol was initiated and further developed into a full global intranet software program, an important element of the Corporate Quality System. |

| Awards | Completing M/PCpS Engineering Training |

|---|---|

|

|

| Hong Kong, Doumen and Zhuhai Facilities completing their M/PCpS training in China. | |

| 5 S & Demand-Based Flow | Lean Manufacturing |

|---|---|

|

|

|

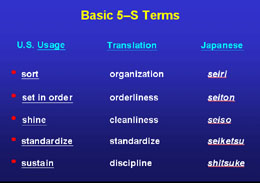

In the first stage of M/PCpS - Process Delineation, the teams started by implementing 5S (Seiri, Seiton, Seison, Seiketsu and Shitsuke, or housekeeping, workplace organization, keep cleanliness, standardize and discipline) and also used decomposable mapping. |

| Home | | ASC | | M/PCpS | | Six Sigma | | VRI | | Training | | Books | | Software | | Articles | | Clients | | Email Us |

| © Copyright, 1995-2025, Advanced Systems Consultants. All Rights Reserved. Scottsdale, Arizona 85261-5257 |